ANSI Z358.1

ANSI Z358.1 | Safety

ANSI/ISEA Z358.1 Emergency Shower & Eye Wash Testing

The standard guiding the placement, functionality, and maintenance requirements for ANSI/ISEA Shower Eye Wash Testing, which was last revised in 2014. In its current form, it is the clearest and most useful tool for protecting workers from eye, face, and body injuries resulting from caustic and corrosive materials introduced by workplace incidents such as spills, […]

ANSI Z358.1 | Safety

Top 5 tips for Purchasing, Placing, & Maintaining Safety Eye Washes & Emergency Showers

Best Practices Emergency Eye Washes & Showers For many employers, selecting and maintaining safety equipment for OSHA eye wash station requirements is a small component of their overall safety plan. There are many pre-emergency measures that are necessary to ensure a safe environment for team members, as well as meeting complex OSHA requirements. Emergency response […]

ANSI Z358.1 | News and Events | Safety

Haws Awarded SHARP Status (Safety and Health Achievement Recognition Program)

On August 7, 2018, Haws Corporation® was awarded SHARP status by the Nevada Division of Industrial Relations. SHARP, the Safety and Health Achievement Recognition Program, is an OSHA cooperative program that recognizes businesses with exemplary safety and health programs and lower than average injury rates. As a manufacturer of emergency equipment for more than 60 years, […]

ANSI Z358.1

Emergency Eyewashes & Showers: Q&A with ANSI Expert

Answers provided by Justin Dunn, Haws Product Specialist / Trainer How often do I have to test my showers and eyewashes? Testing is required on both a weekly and annual basis. Weekly test consists of a quick on/off “bump” test to ensure water flow to the equipment and clear out the dead leg in the […]

ANSI Z358.1 | Safety

Complimentary Site Survey of your Eyewashes and Showers

Have emergency showers and eyewashes in your facility? Do you know if they are compliant with the most recent ISEA/ANSI Z358.1- 2014 Standard? We are offering you a COMPLIMENTARY full day site inspection of you existing emergency response equipment, regardless of brand. And that’s not even the best part… Once the physical equipment inspection is […]

ANSI Z358.1 | Safety

Irrigate eyes like medical pros

[First seen in ISHN Magazine June 2018] Introduce the flushing fluid at the inner corner of the eye An injury can change life in an instant. According to the National Safety Council, occupational injuries occur every seven seconds in the United States. Luckily, through the years, stringent regulation and a growing concern for the health […]

ANSI Z358.1 | Safety

Six Sigma and Safety: Using Data to Improve Outcomes

Six Sigma is a set of tools and processes designed to reduce defects and improve processes. Introduced by Bill Smith from Motorola in 1986, the Six Sigma system has since been adopted by large publicly traded companies like GE, Amazon, Bank of America, 3M, and more. A significant portion of Six Sigma practices are designed around reducing […]

ANSI Z358.1 | Safety

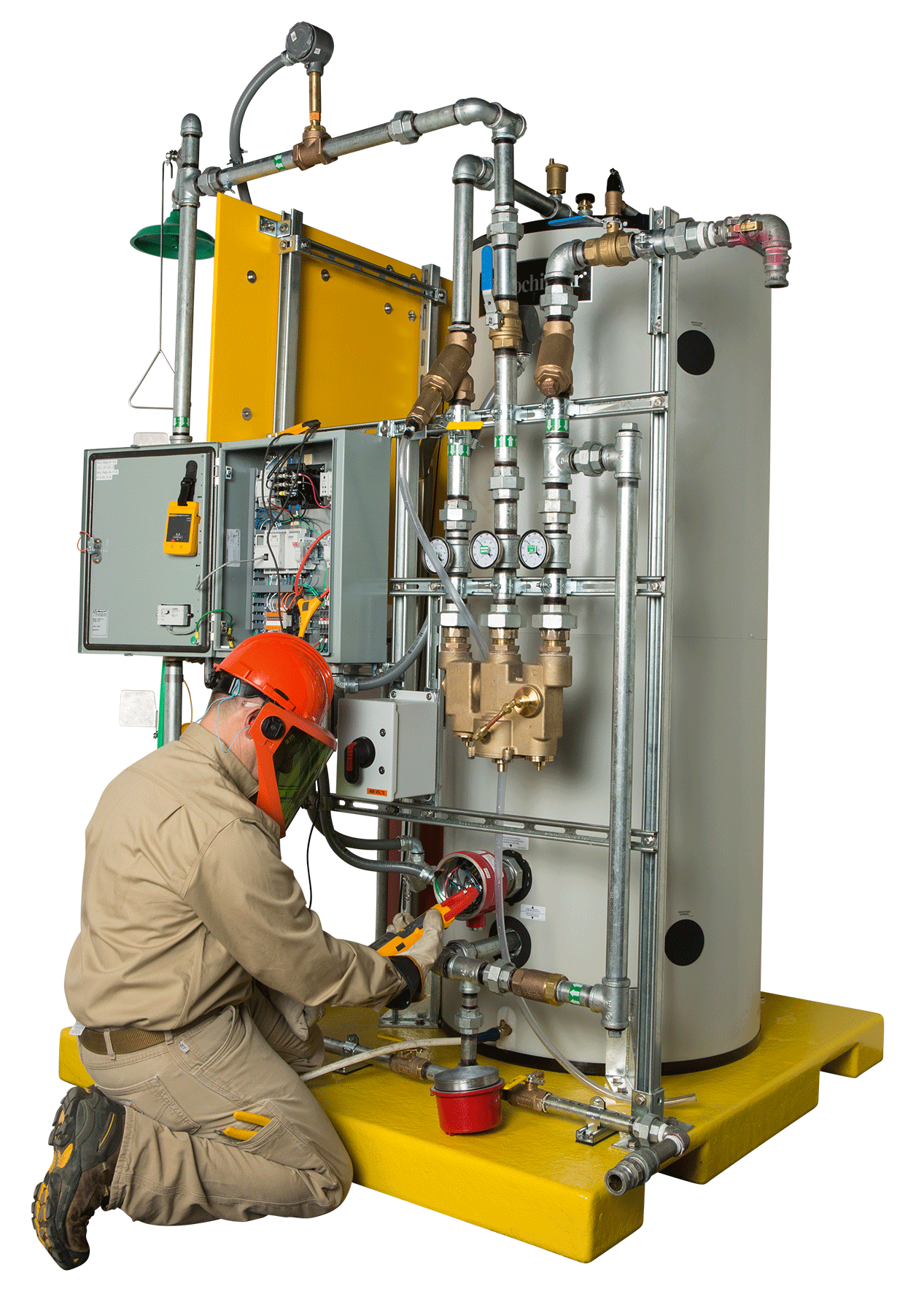

Creating a ‘Comfort Zone’ for Emergency Equipment Water Temperature

[via OH&S Magazine May 2018 Issue] Creating a “Comfort Zone” for Emergency Equipment Water Temperature By: Samantha Hoch, Product Marketing Specialist at Haws® Tempered water has been a hot topic of late, but just as many installations need cooling of high-temperature supply water. Moving water transfers heat, either increasing the temperatures of the objects it […]

ANSI Z358.1 | News and Events | Safety

Haws Satisfies Total Customer Solution with Addition of Haws® Services

Haws is excited to announce the acquisition of Zevado™, Haws’ former third-party service provider. Introducing Haws Services, a warranty and field service provider for emergency shower and eyewash products of all brands to ensure equipment is compliant and functioning properly. This new offering includes: • Factory trained and certified Subject Matter Experts (SME’s) • Remote […]

ANSI Z358.1 | News and Events

OSHA Compliance News: Mistakes that hurt

Organization: Felker Brothers Corp., Marshfield, WI. Business: Pipe manufacturer. Agency: OSHA. Penalty: $110,458 (proposed). Reason for fine: Combustible materials were located within 35 feet of welding activities. Note: OSHA said wooden racks and form plugs were less than 35 feet away from hot work areas. The employer was also cited because machines designed for fixed […]

ANSI Z358.1 | News and Events | Safety

OSHA penalties go up by 2% in addition to the recent 80% increase

Effective January 2, civil penalties for violations of workplace safety and health standards are 2 percent higher, with a new maximum fine of nearly $130,000. OSHA increased its penalties to adjust for inflation as required by the Federal Civil Penalties Inflation Adjustment Act of 2015, which initially raised civil penalties by 78 percent after over […]

ANSI Z358.1 | News and Events | Safety

OSHA and ANSI Requirements for Eyewash and Safety Showers

[via LabManager.com] ANSI standard Z358.1 is detailed in terms of defining what is appropriate for safety showers and eyewash stations. By Vince McLeod | June 05, 2017 As lab managers and employees, we know that many inorganic chemicals (such as the mineral acids and alkalis) are corrosive to the skin and […]